-

1.2738 Plastic Mold Steel

1.2738 Mold Steel is a steel suitable for galvanic corrosion operations, originating in Germany, for acidic plastics and molds that require a good finish.

Function:

1. Uniform material with high purity

2. Excellent polishing performance and lithography performance

3. Good electrical processing performance and skin texture processing performance¥ 0.00Learn more

-

P20 Plastic Mold Steel

KD special steel P20 pre-hardened plastic mold steel is a high-quality plastic mold steel produced using VAD processing technology. The national standard name is: 3Cr2Mo mold steel.¥ 0.00Learn more

-

1.2311H Plastic Mold Steel

1. 2311H pre-hardened plastic mold steel, after heat treatment, has good processing and polishing properties, and is more suitable for EDM. It can be used in the general manufacture of large plastic moulds, and can also be used as a plastic mold base.¥ 0.00Learn more

-

S7 Tool Steel

S7 tool steel is an impact-resistant tool steel with excellent toughness, high strength and moderate wear resistance. It has maximum shock and high compressive strength, which makes it have good resistance to deformation in use while maintaining good toughness. S7 tool steels are easy to machine in the annealed condition and easy to heat treat. It can be quenched in air with minimal deformation when hardened.¥ 0.00Learn more

-

FT33 Cold Work Mold Steel

FT33 (Cr12MoV) is a high-carbon, high-chromium alloy steel for molds, known for its excellent hardenability and wear resistance. It exhibits minimal dimensional changes during quenching, along with outstanding toughness. After heat treatment, it attains high hardness and exceptional wear resistance. Additionally, it demonstrates good dimensional stability and is well-suited for high-precision production.¥ 0.00Learn more

-

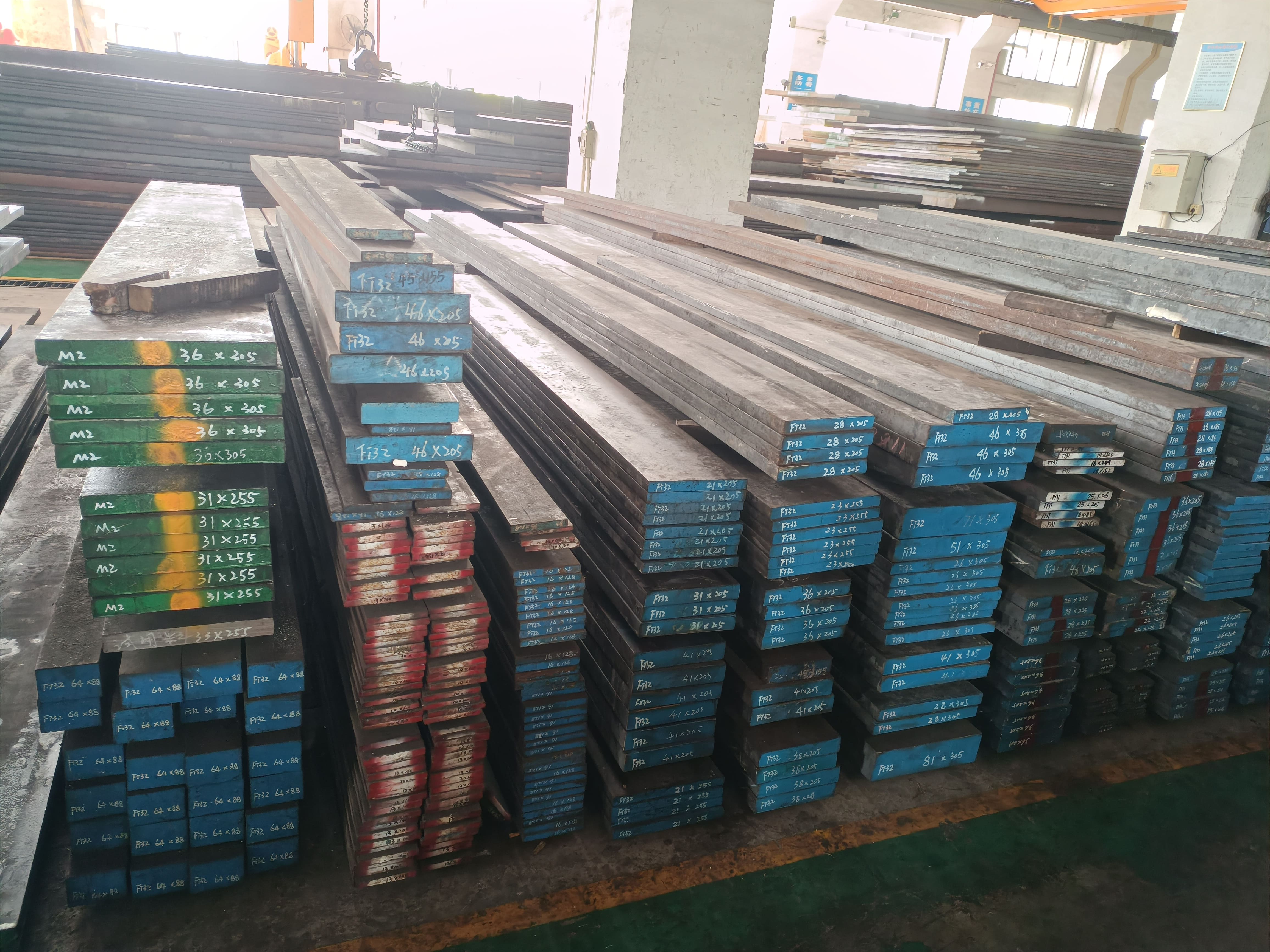

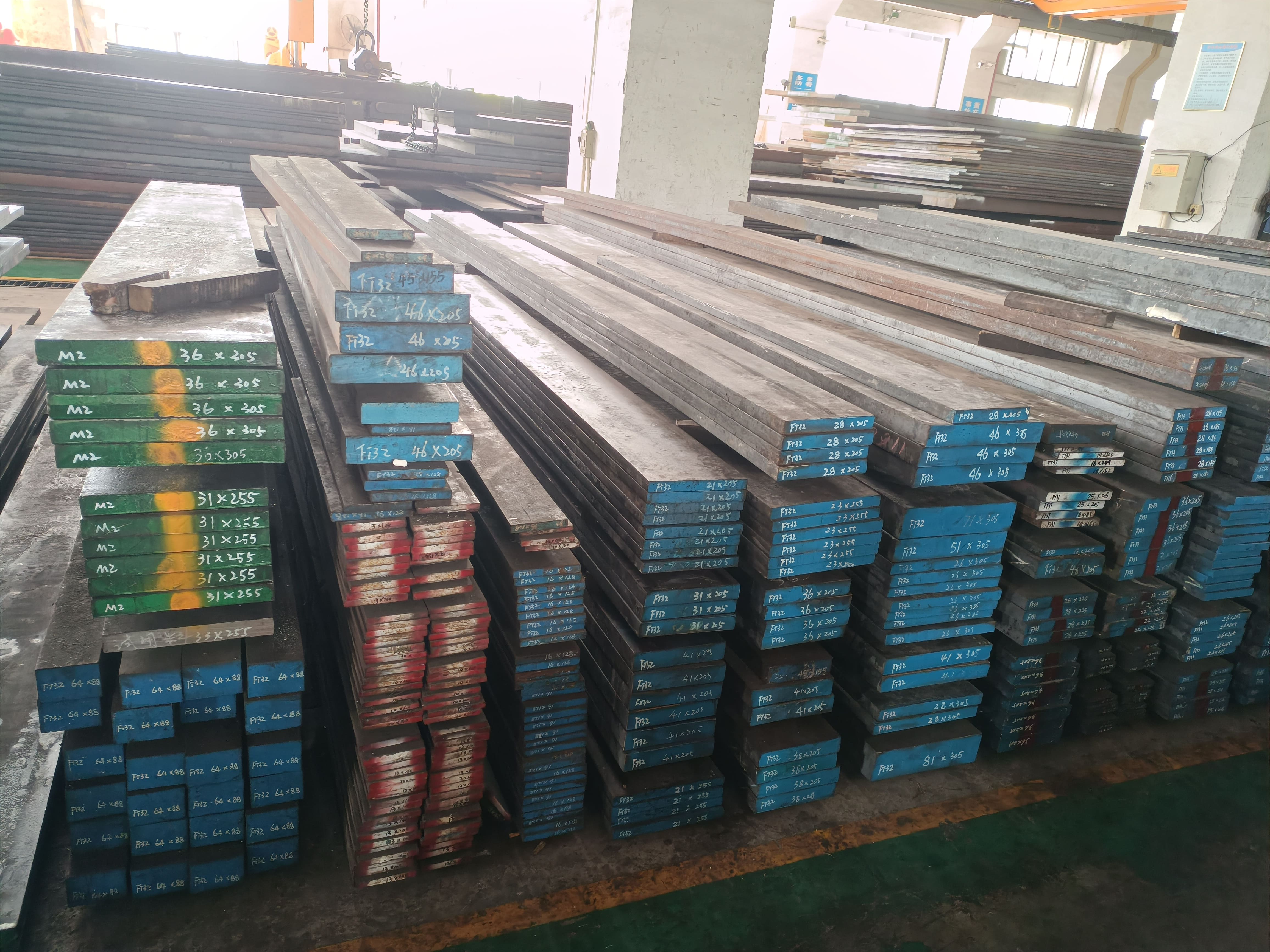

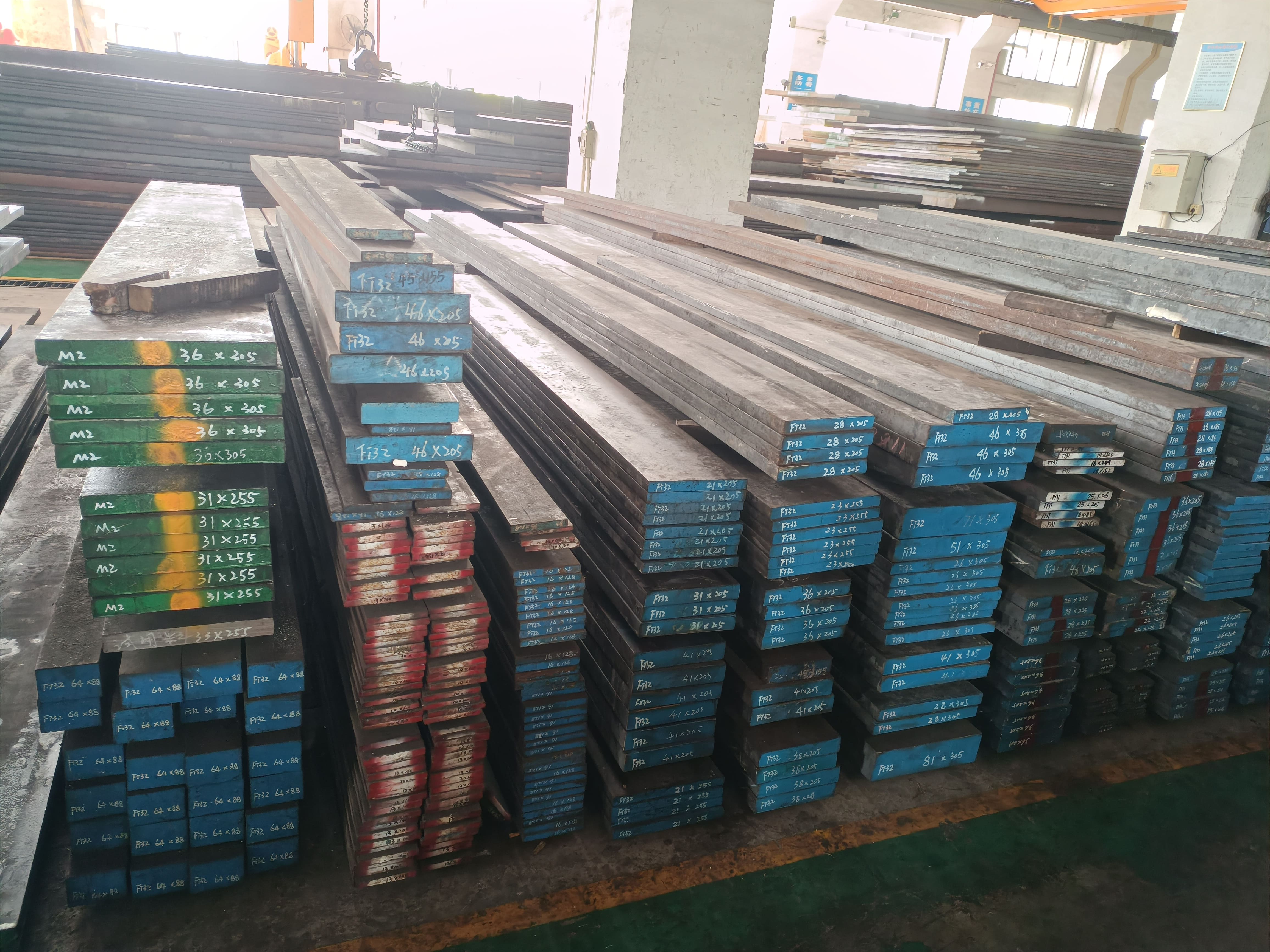

FT32 Cold Work Mold Steel

FT32 is a commonly used cold work mold steel. Its smelting process and metal composition were determined with reference to imported DC53 tool steel, 1.2379 tool steel, and D2 cold work tool steel. In China, it is known as Cr12Mo1V1 tool steel, and FT32 tool steel is equivalent to it. It is a high-quality material with various characteristics, but it cannot completely replace similar imported materials.¥ 0.00Learn more

-

1.2738 Plastic Mold Steel

1.2738 Mold Steel is a steel suitable for galvanic corrosion operations, originating in Germany, for acidic plastics and molds that require a good finish.

Function:

1. Uniform material with high purity

2. Excellent polishing performance and lithography performance

3. Good electrical processing performance and skin texture processing performance¥ 0.00Learn more

-

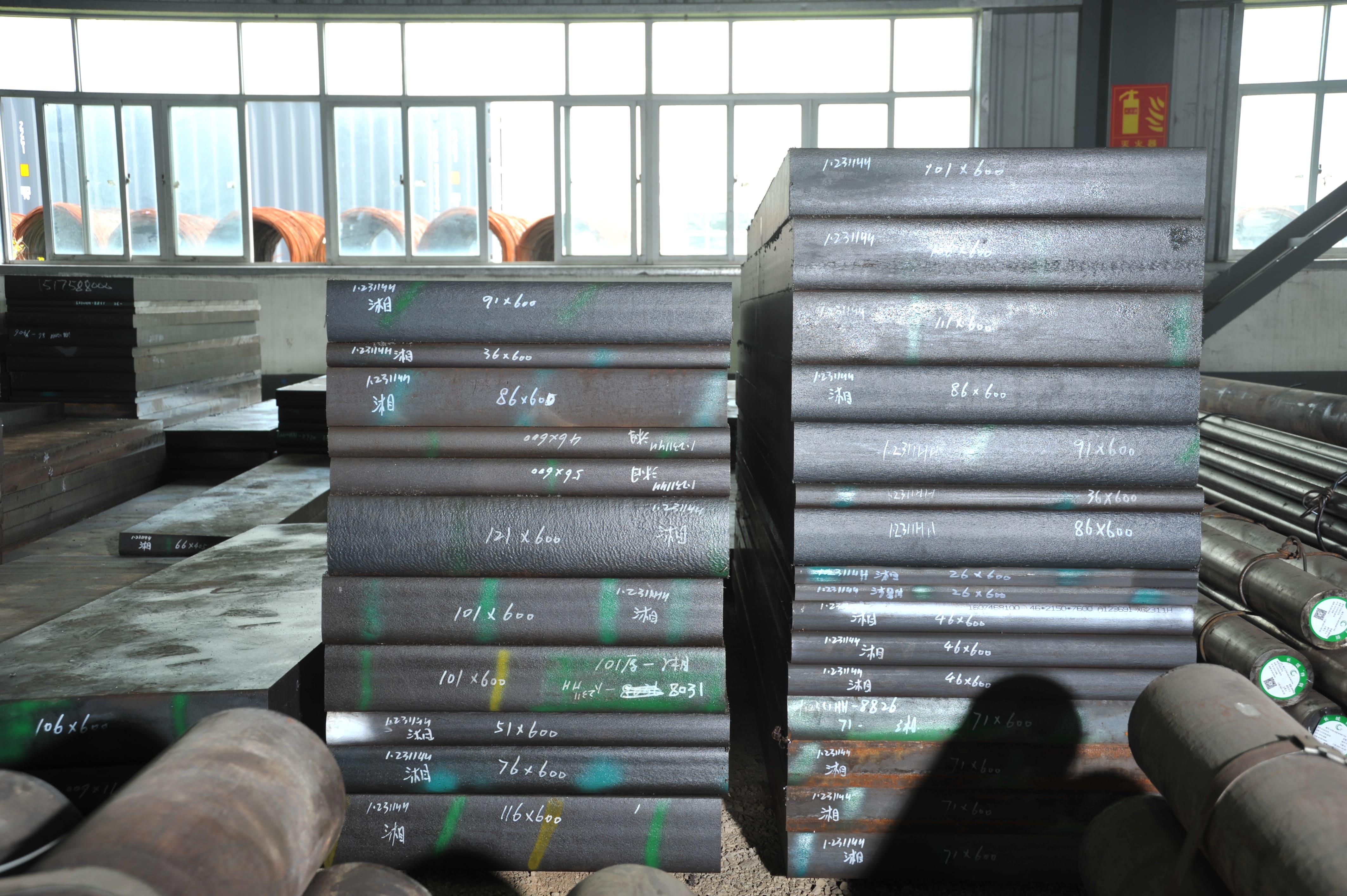

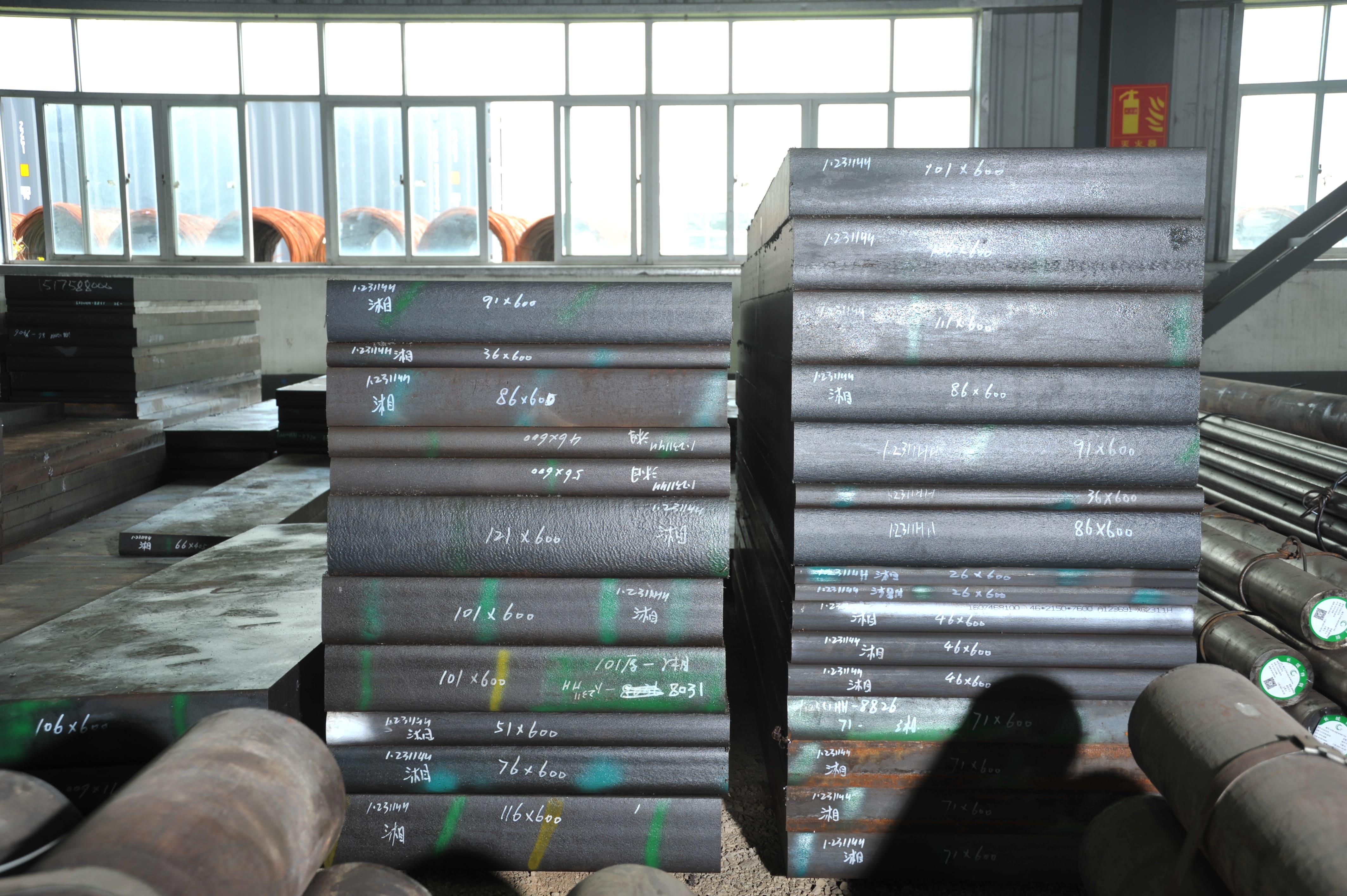

1.2344 Hot Work Mold Steel

1.2344 is a German brand and is a pressure-resistant hot work mold steel. After electroslag remelting, the steel material is uniform, with good hardenability, excellent machinability and polishing performance, high toughness and plasticity, good high and low temperature wear resistance, high temperature fatigue resistance and heat resistance.¥ 0.00Learn more

-

P20 Plastic Mold Steel

KD special steel P20 pre-hardened plastic mold steel is a high-quality plastic mold steel produced using VAD processing technology. The national standard name is: 3Cr2Mo mold steel.¥ 0.00Learn more

-

FT33 Cold Work Mold Steel

FT33 (Cr12MoV) is a high-carbon, high-chromium alloy steel for molds, known for its excellent hardenability and wear resistance. It exhibits minimal dimensional changes during quenching, along with outstanding toughness. After heat treatment, it attains high hardness and exceptional wear resistance. Additionally, it demonstrates good dimensional stability and is well-suited for high-precision production.¥ 0.00Learn more

-

FT32 Cold Work Mold Steel

FT32 is a commonly used cold work mold steel. Its smelting process and metal composition were determined with reference to imported DC53 tool steel, 1.2379 tool steel, and D2 cold work tool steel. In China, it is known as Cr12Mo1V1 tool steel, and FT32 tool steel is equivalent to it. It is a high-quality material with various characteristics, but it cannot completely replace similar imported materials.¥ 0.00Learn more

-

D2 Cold Work Mold Steel

D2 is a kind of mold steel, the hardness can reach 60HRC after heat treatment, it is a kind of semi-stainless steel. D2 steel has good wear resistance and moderate toughness. The disadvantage is that the corrosion resistance is slightly insufficient. It is a more suitable steel for practical use.¥ 0.00Learn more

-

FT64 Plastic Mold Steel

FT64 steel is a domestic medium-carbon high-chromium corrosive plastic mold steel, which belongs to the Austin type mold steel and has good horse formability. After quenching and recovery, it has excellent corrosion resistance, polishability, high strength and wear resistance. But the soldering is not good and needs attention. Hardening is usually no longer required; in special cases, can be hardened to 40HRC round bar with a recovery hardness higher than 50HRC and has super mirror machinability¥ 0.00Learn more

-

4Cr13 Tool Steel

4Cr13 steel code S-136, is a martensitic stainless steel, the steel has good machinability, after heat treatment (quenching and tempering), has excellent corrosion resistance, polishing performance, high strength and wear resistance, It is suitable for the manufacture of plastic molds under high load, high wear-resistant and corrosive media, transparent plastic product molds, etc., such as heat oil pumps, valve plates, valve bearings, medical equipment, springs and other parts.¥ 0.00Learn more

-

9Cr18Mo Stainless Steel

9Cr18Mo stainless steel is a high carbon chromium stainless steel used in the manufacture of bearing rings and rolling elements. The standard is GB/T1220-2007, and the grade becomes 102Cr17Mo.

9Cr18 is a high carbon chromium martensitic stainless bearing steel. After quenching, it has high hardness and wear resistance, as well as dimensional stability at high and low temperatures.¥ 0.00Learn more

-

1045 Carbon Steel

1045 steel is a commonly used high-quality carbon structural steel, also known as "45" steel, corresponding to Japanese standard S45C, American standard 1045, and German standard c45. It is characterized by higher strength and deformation resistance than ordinary A3 steel, and 45 steel is widely used in industrial machinery.¥ 0.00Learn more

-

1050 Carbon Steel

1050 carbon structural steel is a high-strength medium-carbon steel, also known as 50 steel in the industry. 50 steel is a common material for shaft parts. The price is cheap, the cutting performance is better after quenching and tempering (or normalizing), and the comprehensive mechanical properties such as higher strength and toughness can be obtained, and the surface hardness after quenching can reach 45-52HRC.¥ 0.00Learn more