FT32 Cold Work Mold Steel

One. Product Description

FT32 is a commonly used cold work mold steel. Its smelting process and metal composition were determined with reference to imported DC53 tool steel, 1.2379 tool steel, and D2 cold work tool steel. In China, it is known as Cr12Mo1V1 tool steel, and FT32 tool steel is equivalent to it. It is a high-quality material with various characteristics, but it cannot completely replace similar imported materials.

Two. Quality Standard

GB/T 1220-1992 Standard Specification

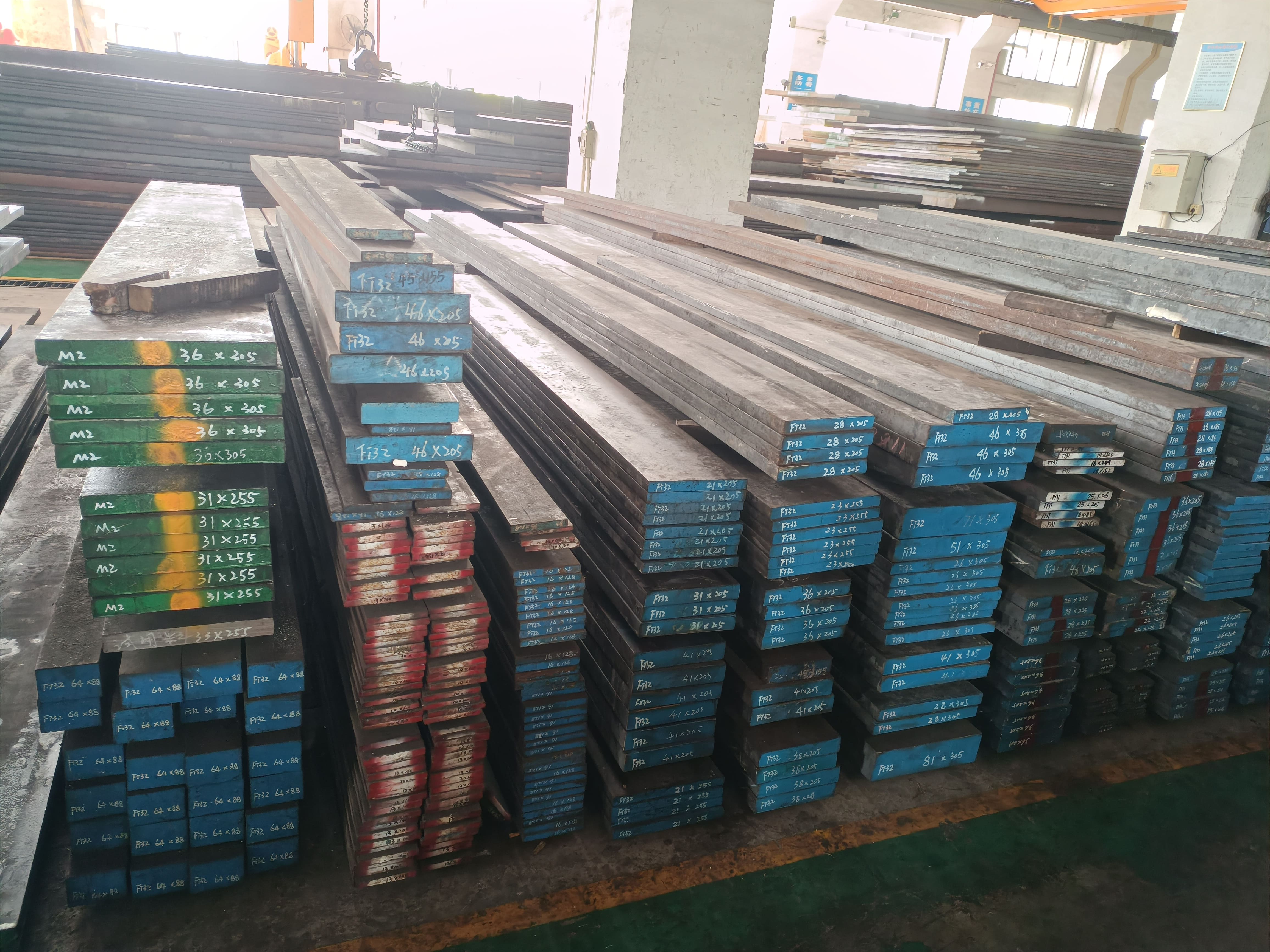

Three. Product Specifications

Four. Equivalent Grade of FT32 Mold Steel - For Reference Only

|

|

China GB |

Germany DIN |

US AISI |

Sweden SS |

Japan DAIDO |

Japan JIS |

South Korea KS |

Austria BOHLER |

IOS |

|

FT32 |

Cr12MoV |

1.2739 (X155CrV Mo121) |

D2 |

XW42 |

DC11 |

SKD11 |

STD11 |

K11O |

160CrM oV12 |

Five. Product Features and Uses

Features:

1. High purity, uniform structure hardness

2. Anti-wear, high strength

3. Both wear resistance and toughness

4. Excellent quenching performance

Use:

1. FT32 is suitable for precision metal molds, semiconductor molds, precision parts, etc.

2. FT32 is suitable for all kinds of cold stamping molds, thread rolling plates, blow molding molds, structural parts, etc., with high brain mold and long service life.

Six. Product Detailed Information

FT32 mold steel is a high wear-resistant micro-deformation cold work mold steel with a carbon content of up to 1.6% and a chromium content of 12%. After professional heat treatment, the hardness can reach above 60HRC. D2 mold steel can be used to make cross sections. Large and complex shapes. Cold work molds that withstand high impact and require high wear resistance, such as silicon steel sheet molds, cold shears, trimming molds, metal stamping molds, wire drawing molds, stainless steel sheet molds, high hardness molds, thread rolling molds, etc. Hardware has the characteristics of high wear resistance, hardenability, micro-deformation, high stability, high bending strength, etc., second only to high-speed steel, is the preferred steel for stamping molds and cold heading molds.

FT32 mold steel has the following characteristics:

1. Good processability, excellent heat treatment dimensional stability.

2. Excellent processing performance.

3. Excellent dimensional stability during quenching.

4. After quenching and tempering, the surface hardness is high, and it cooperates well with the toughness of the body.

FT32 steel is widely used around the world because of its high carbon, high chromium, ledeburite steel and other characteristics, and pays more attention to hardenability, hardenability and high wear resistance, so D2 steel has better high temperature oxidation resistance and heat treatment properties. deformability. Smaller in size, it is very suitable for manufacturing various high-precision, long-life cold work molds, cutting tools and measuring tools, etc., and is currently pursued by many automotive cold stamping mold factories. The workpieces and molds produced with FT32 mold steel have been indirectly distributed to well-known domestic and foreign auto companies such as Geely Apocalypse, JAC, Southeast, Honda, Ford, GM, BMW, Audi, Porsche, etc.

|

FT32 mold steel expansion coefficient |

||||

|

Temperature/ ℃ |

20-100 |

20-200 |

20-300 |

20-400 |

|

Linear (shadow) expansion coefficient/ ℃-1, x10-6 |

10.5 |

11.5 |

11.9 |

12.2 |

Processing:

Stress relief annealing: After rough machining of the workpiece, heat it to 600~650℃, keep it for 2 hours, cool it to 500℃ with the furnace, and let it cool.

Quenching: The workpiece is slowly heated up to 600 °C, the first preheating and holding for 20 minutes, the temperature is uniform and then raised to 850 °C, the second preheating and holding is 30 minutes, and finally the temperature is raised to 1020~1040 °C, holding for 25~40min, and the blasting air cold.

Tempering: It should be tempered immediately after quenching, at least twice, and the holding time is not less than 2 hours each time. Quenching, preheating at 820±15℃, heating at 1000±6℃ (salt bath) or 1010±6℃ (furnace controlled atmosphere), holding for 10~20min, air cooling, tempering at 200±6℃.

Note: Temper in time after quenching to prevent cracking and surface decarburization. Gauge and high-precision mold should be treated at -70 ℃ low temperature and tempered at high temperature to reduce workpiece deformation. The high temperature tempering temperature is 500~560℃, and the hardness is greater than 58HRC.

Hardness: annealing ≤255HB, indentation diameter ≥3.8mm, quenching>59HRC. Company delivery condition is soft annealed to 255HB.

Similar material grades in other regions:

Japan SKD11 mold steel, Germany X165CrMoV12~1.2601.

|

Diagrams of various thermal external treatment methods for FT32 steel |

|||

|

Project |

Heating Temperature℃ |

Cooling Method |

Hardness |

|

Annealing |

870~890 |

≤30C/H, cool to 500℃ and release |

≤255HB |

|

Quenching |

Method A: 980~1040 |

Oil-cooled or Air-cooled |

60~65HRC |

|

Method B: 1060~1100 |

Oil-cooled or Air-cooled |

60~65HRC |

|

|

Tempering |

Method A: 1080~200/1 time |

Air cooling |

60~64HRC |

|

Method B: 510~540/2 times |

Air cooling |

60~64HRC |

|