-

1.2738 Plastic Mold Steel

1.2738 Mold Steel is a steel suitable for galvanic corrosion operations, originating in Germany, for acidic plastics and molds that require a good finish.

Function:

1. Uniform material with high purity

2. Excellent polishing performance and lithography performance

3. Good electrical processing performance and skin texture processing performance넶2 ¥ 0.00 -

P20 Plastic Mold Steel

KD special steel P20 pre-hardened plastic mold steel is a high-quality plastic mold steel produced using VAD processing technology. The national standard name is: 3Cr2Mo mold steel.

넶3 ¥ 0.00 -

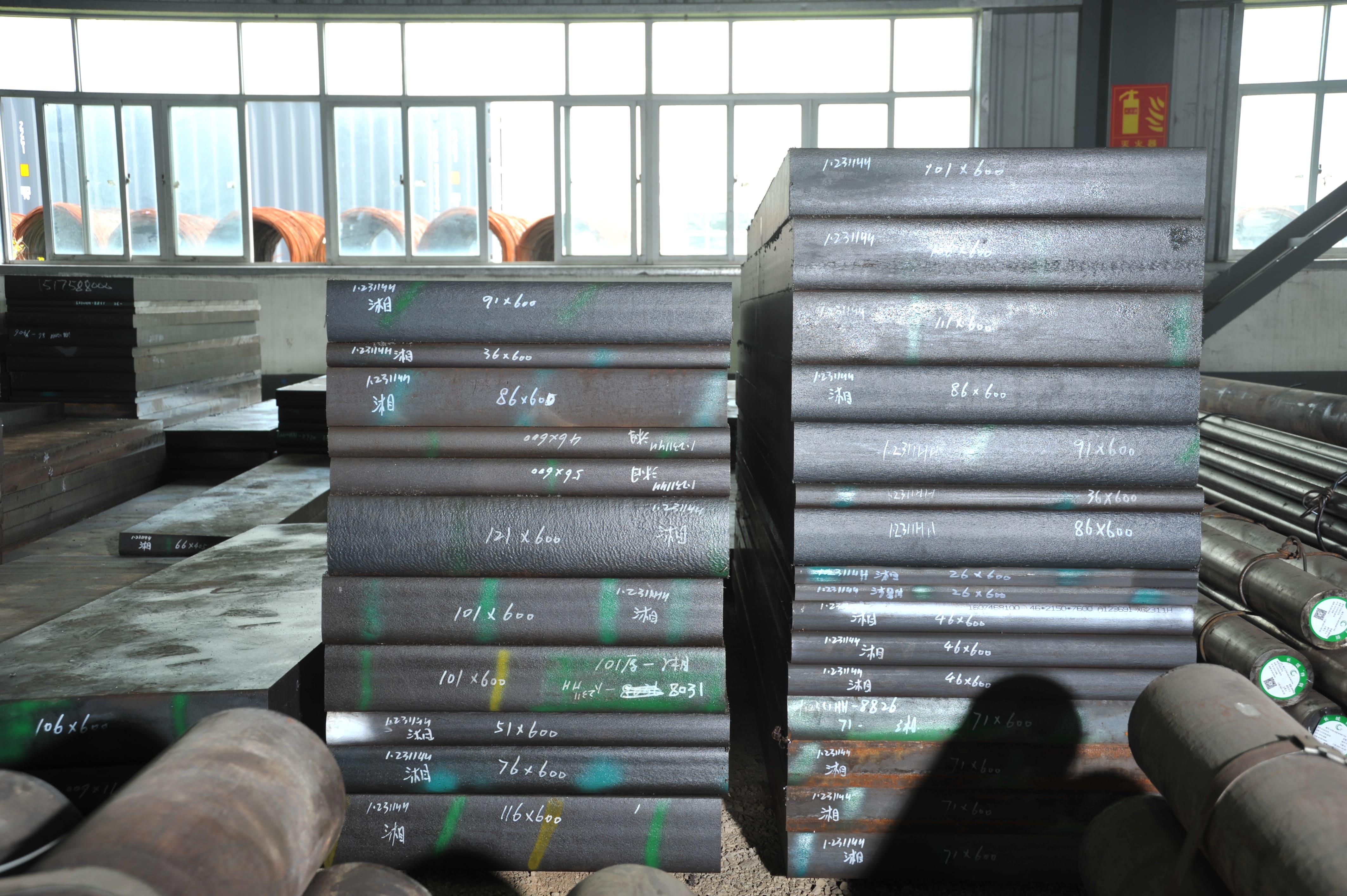

1.2311H Plastic Mold Steel

1. 2311H pre-hardened plastic mold steel, after heat treatment, has good processing and polishing properties, and is more suitable for EDM. It can be used in the general manufacture of large plastic moulds, and can also be used as a plastic mold base.

넶5 ¥ 0.00 -

718 Plastic Mold Steel

718 mold steel is a grade of pre-hardened hot work mold steel, corresponding to my country's GB standard 3Cr2NiMo mold steel. The steel has excellent mechanical properties and machinability, and is widely used in the mold industry, especially the processing and production of plastic molds.

넶5 ¥ 0.00 -

FT64 Plastic Mold Steel

FT64 steel is a domestic medium-carbon high-chromium corrosive plastic mold steel, which belongs to the Austin type mold steel and has good horse formability. After quenching and recovery, it has excellent corrosion resistance, polishability, high strength and wear resistance. But the soldering is not good and needs attention. Hardening is usually no longer required; in special cases, can be hardened to 40HRC round bar with a recovery hardness higher than 50HRC and has super mirror machinability

넶5 ¥ 0.00

Plastic Mold Steel

Plastic mold steel is a kind of mold steel used for plastic production

Plastic mold steel can generally be divided into:

Age-hardening plastic mold steel (including mirror mold steel), corrosion-resistant plastic mold steel, carburized plastic mold steel, pre-hardened embedded mold steel (including free-cutting steel), quenched and tempered plastic mold steel and hardened Type plastic mold steel six categories. The most widely used are age-hardening plastic mold steel, carburized plastic mold steel and pre-hardened plastic mold steel.

A large number of plastic products need to be molded in the production process, which has greatly promoted the development of the mold industry. Mold material is the key factor affecting the quality, performance and service life of the mold, and it is also a very important part of the development of the mold industry. Plastic mold materials are still dominated by mold steel, and the development of mold steel has promoted the development of industrial products in the direction of advanced, diversified, personalized, and high added value.

Mainly used:

1. Develop materials that are easy to process and have good polishing properties

With the production of precision parts such as optical discs, magnetic disks, and prisms, the requirements for easy-to-process mirror steels have increased. This kind of steel contains less non-metallic impurities, fine and uniform metallographic structure, and no fiber directionality. It is the main development direction of plastic mold steel.

2. Corrosion-resistant steel

Molds are prone to rust and corrosion during long-term operation and maintenance, and with the addition of various ingredients in plastic molding, molds are more likely to be corroded. Therefore, it is required to improve the corrosion resistance of the base metal body, and some corrosion-resistant stainless steel materials have been developed.

3. Maraging alloy steel

This kind of steel has sufficient mechanical properties and outstanding process properties, especially high strength, toughness, wear resistance, and low thermal expansion coefficient. It is a good steel for making injection molds, but it is expensive.

4. Carbide

It is mainly used to make molds with high life expectancy and large batch production of parts

-

Tower Structure

Tower structures are a widely used design concept in modern architecture and engineering, standing out for their excellent stability and remarkable load-bearing capacity. The importance and role of steel in the design and construction of tower structures cannot be overlooked. Steel, as a fundamental building material in tower structures, provides a solid framework, endowing buildings with limitless creative space and powerful support.

넶4 2023-02-23 -

The key role of steel's weight-bearing capacity in modern roof construction.

This article highlights the crucial role of steel's weight-bearing capacity in modern roof construction. Steel's exceptional strength, stability, and weight characteristics make it an ideal choice for handling heavy wind and snow loads, as well as other external pressures. It discusses how steel positively impacts architectural design, structural stability, and durability in modern roofs.

넶5 2023-02-23

News

Products

Offers excellent, comprehensive customer service every step of the way. Before you order, make real time inquiries through...

Inquiry

Contact us

106 Jinghai West Road, Chang 'an Town, Dongguan City, Guangdong Province, China

- +86-0769-85441280

- +86 13201032726

- info@mouldsteels.com

Remark:

Office Work Time:

9:00 am – 6:00 pm

(except on state holidays)

@Copyright 2023 Dongguan Kaiding Hardware Co., Ltd.