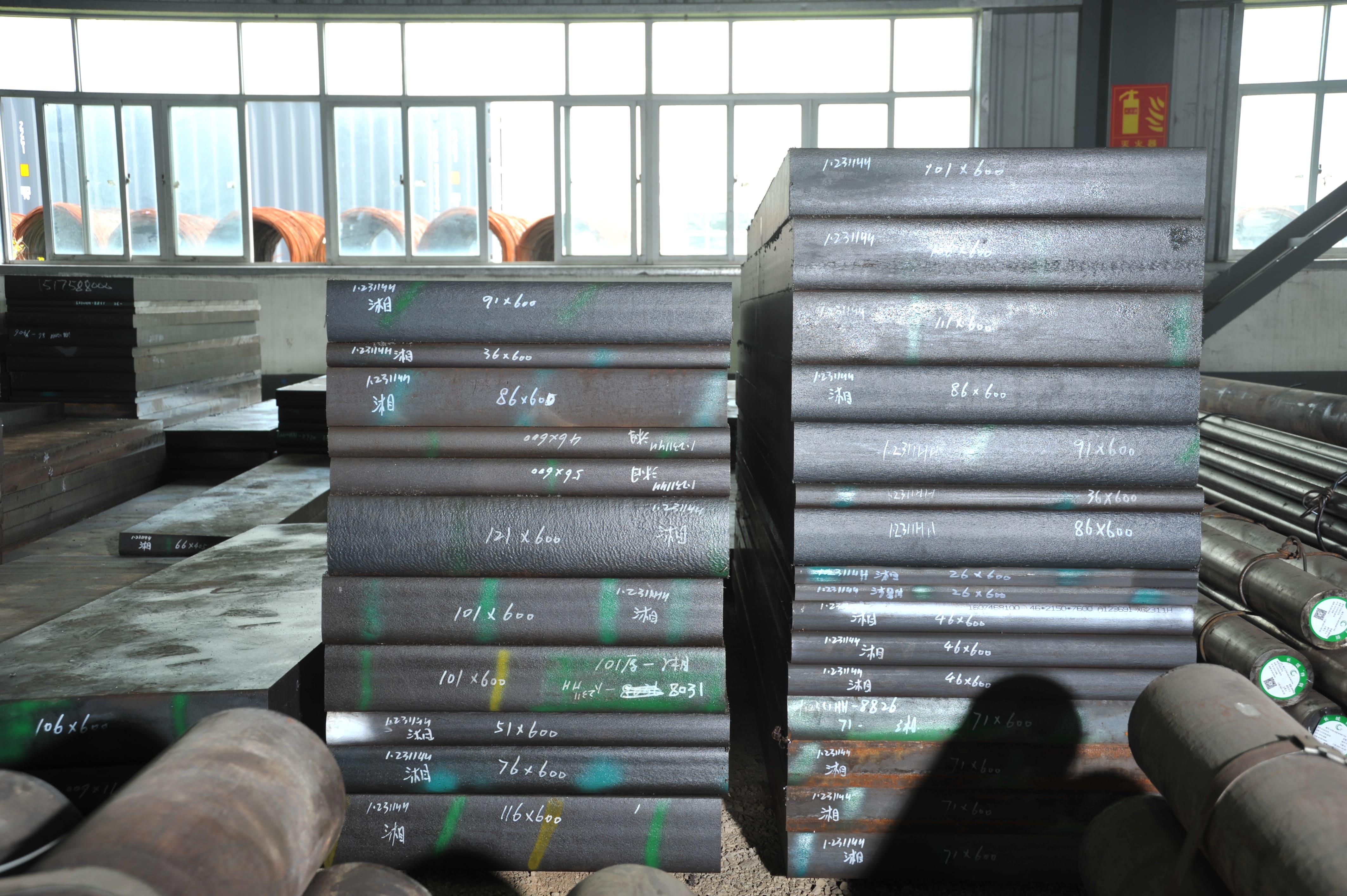

1.2311H Plastic Mold Steel

One. Product Description

1. 2311H Pre-Hardened Plastic Mold Steel, after heat treatment, has good machining and polishing properties, and is more suitable for EDM. Can be used for general manufacturing of large plastic molds and plastic mold bases.

Two. Quality Standard

EN ISO 4957-2001 Standard Specification for Tool Steels

Three. Product Specifications

Four. Equivalent Grade of 1.2311H Mold Steel - For Reference Only

|

|

China GB |

US AISI |

Japan JIS |

Germany DIN |

Sweden SS |

IOS |

|

1.2311H |

3Cr2Mo |

P20H |

PDS5 |

1.2311H |

618H |

35CrMo2 |

Five. Product Features and Uses

Features:

1. High polishability, good machinability, excellent toughness, nitriding or chrome plating.

2. The steel has high purity after vacuum degassing and refining, and is suitable for plastic molds that need to be polished or etched.

3. Delivered in a pre-hardened state, without heat treatment, it can be directly used for mold processing, shortening the construction period.

4. After forging, the structure is dense, 100% ultrasonic flaw detection, no pores and pinhole defects.

Use:

1. For zinc, aluminum, magnesium and its alloy mold-casting molds.

2. Thermoplastic injection mold, extrusion mold.

3. Cold structural parts.

4. Commonly used in the manufacture of TV casings, washing machines, refrigerator inner casings, buckets, etc.

Six. Product Detailed Information

1.2311H plastic mold steel, produced by "Ultra-Pure" process, pre-hardened, showing a high degree of microscopic purity and excellent uniform structure, excellent polishing and lithography performance, after heat treatment, processing, polishing performance is good, can be nitrided, It is suitable for surface treatment such as chrome plating, with uniform hardness (up to 400mm thick), good toughness and good machinability. The organization is martensite and bainite.

1.2311HH plastic mold steel is a conventional melting (EF+LF+VD) mold steel, we recommend 1.2311HH to customers who have higher requirements on pattern and polishing.

Heat Treatment:

Quenching treatment: In order to increase the life of the mold to more than 800,000 times, the pre-hardened steel can be quenched and low tempered hardened. During quenching, preheat at 500~600°C for 2~4 hours, then keep at 850~880°C for a certain period of time (at least 2 hours), put it in oil and cool it to 50~100°C, and wait for it to cool in oil and air. After quenching, the hardness can reach 50~52HRC. In order to prevent cracking, it should be tempered at a low temperature of 200 °C immediately. The hardness can be maintained above 48HRC after tempering.