-

FT33 Cold Work Mold Steel

FT33 (Cr12MoV) is a high-carbon, high-chromium alloy steel for molds, known for its excellent hardenability and wear resistance. It exhibits minimal dimensional changes during quenching, along with outstanding toughness. After heat treatment, it attains high hardness and exceptional wear resistance. Additionally, it demonstrates good dimensional stability and is well-suited for high-precision production.

넶4 ¥ 0.00 -

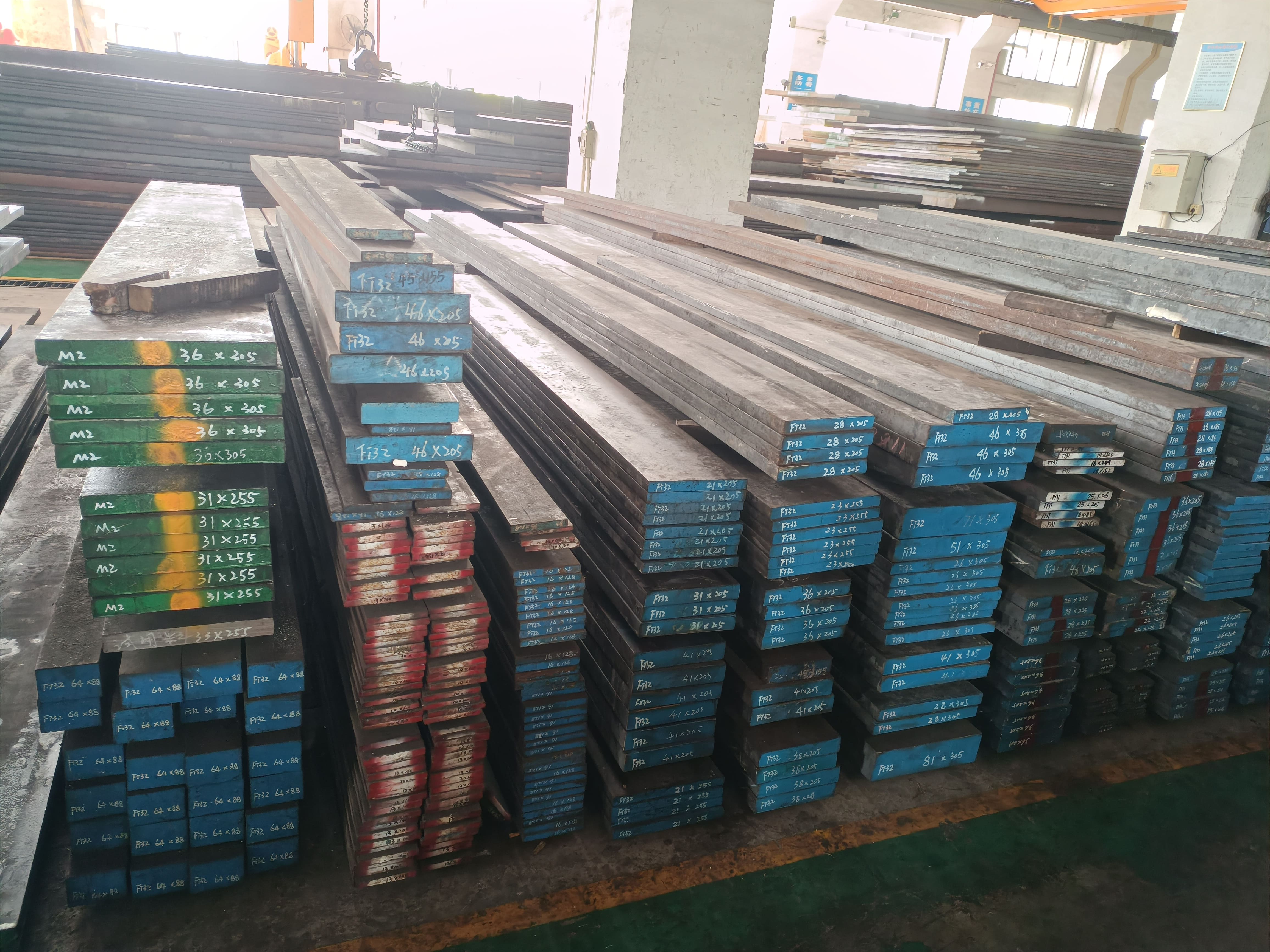

FT32 Cold Work Mold Steel

FT32 is a commonly used cold work mold steel. Its smelting process and metal composition were determined with reference to imported DC53 tool steel, 1.2379 tool steel, and D2 cold work tool steel. In China, it is known as Cr12Mo1V1 tool steel, and FT32 tool steel is equivalent to it. It is a high-quality material with various characteristics, but it cannot completely replace similar imported materials.

넶5 ¥ 0.00 -

D2 Cold Work Mold Steel

D2 is a kind of mold steel, the hardness can reach 60HRC after heat treatment, it is a kind of semi-stainless steel. D2 steel has good wear resistance and moderate toughness. The disadvantage is that the corrosion resistance is slightly insufficient. It is a more suitable steel for practical use.

넶5 ¥ 0.00 -

Cr12 Cold Work Mold Steel

Cr12 Mold Steel is a typical alloy tool steel. It is a widely used cold work mold steel with high strength, good hardenability and wear resistance, but poor impact attenuation. Cold molds and punches, cold shears, drill sleeves, gauges, wire drawing molds, punching molds, thread rolling molds, wire drawing molds and thread rolling molds with high wear resistance requirements.

넶6 ¥ 0.00 -

DC53 Cold Work Mold Steel

DC53 Mold Steel is a new type of general cold work mold steel with strength and toughness close to high speed steel.

DC53 Mold Steel is an improvement over alloy tool steel D2 specified in Standard (JIS) G4404. It eliminates the disadvantage of insufficient hardness and toughness of D2 due to high temperature tempering, and is designed to replace D2 for general and precision molds.넶6 ¥ 0.00

Cold Work Mold Steel

Cold work mold steel refers to the mold steel used to deform or form metal in a cold state

Cold work mold steels are essentially high-carbon steels, which contain relatively low alloy additions of tungsten, manganese, chromium and molybdenum. These alloy additions increase hardness, permitting oil quenching with less distortion than with the W series. and their high carbon content produces adequate wear resistance for short-run applications. It is used for all types of blanking and forming molds, gauges, collets, etc.

The performance of cold work mold steel:

1. High wear resistance

2. High strength and toughness

3. Strong bite resistance

4. Heat-softening ability

Selection method

1. When selecting cold work mold steel, it is necessary to consider the processing method, stress state, material properties of the forming object, production quantity, plate thickness, etc. In addition, the size and dimensional accuracy of the mold are also factors that cannot be ignored.

2. Low-alloy tool steel (SKS) is used for small load or small batch production, cold work mold steel (SKD) is used for heavy load or mass production, and high-speed tool steel and powder high-speed tool steel are used for larger load.

3. Suitable for wear-resistant occasions are cold work mold steel, high-speed tool steel and high-alloy high-speed tool steel, suitable for impact-resistant occasions are 8Cr-2Mo series mold steel and matrix high-speed tool steel.

-

Tower Structure

Tower structures are a widely used design concept in modern architecture and engineering, standing out for their excellent stability and remarkable load-bearing capacity. The importance and role of steel in the design and construction of tower structures cannot be overlooked. Steel, as a fundamental building material in tower structures, provides a solid framework, endowing buildings with limitless creative space and powerful support.

넶4 2023-02-23 -

The key role of steel's weight-bearing capacity in modern roof construction.

This article highlights the crucial role of steel's weight-bearing capacity in modern roof construction. Steel's exceptional strength, stability, and weight characteristics make it an ideal choice for handling heavy wind and snow loads, as well as other external pressures. It discusses how steel positively impacts architectural design, structural stability, and durability in modern roofs.

넶5 2023-02-23

News

Products

Offers excellent, comprehensive customer service every step of the way. Before you order, make real time inquiries through...

Inquiry

Contact us

106 Jinghai West Road, Chang 'an Town, Dongguan City, Guangdong Province, China

- +86-0769-85441280

- +86 13201032726

- info@mouldsteels.com

Remark:

Office Work Time:

9:00 am – 6:00 pm

(except on state holidays)

@Copyright 2023 Dongguan Kaiding Hardware Co., Ltd.